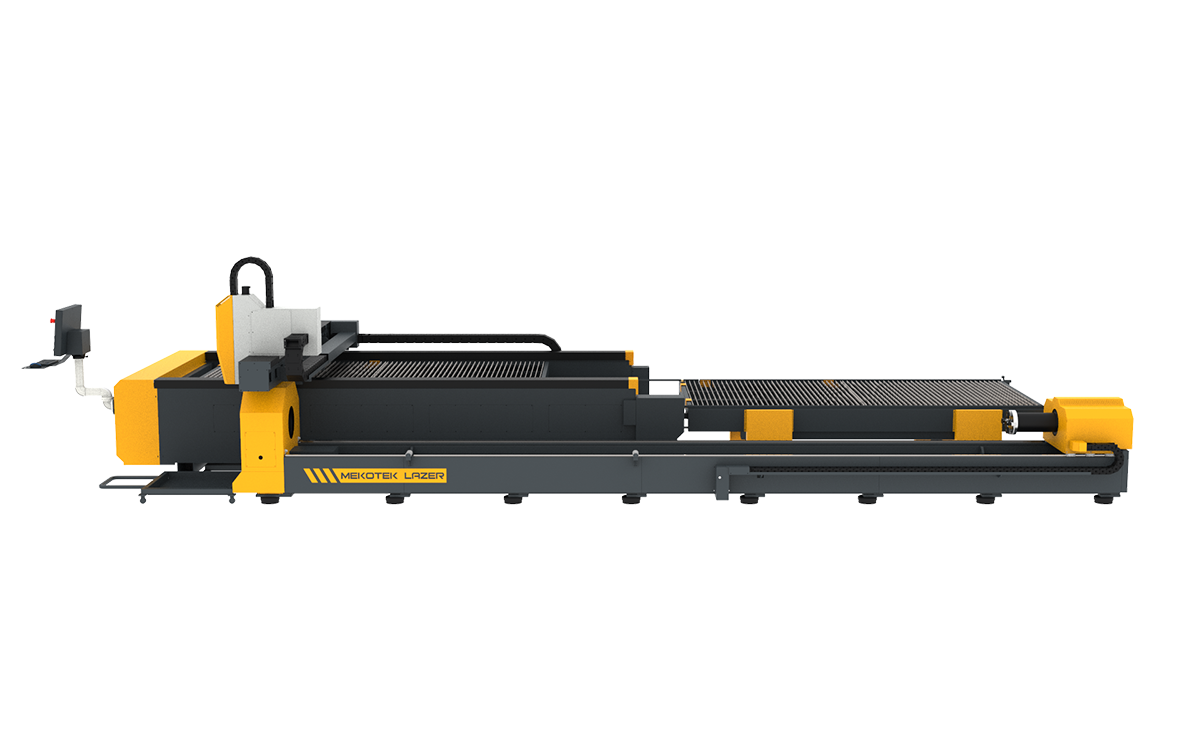

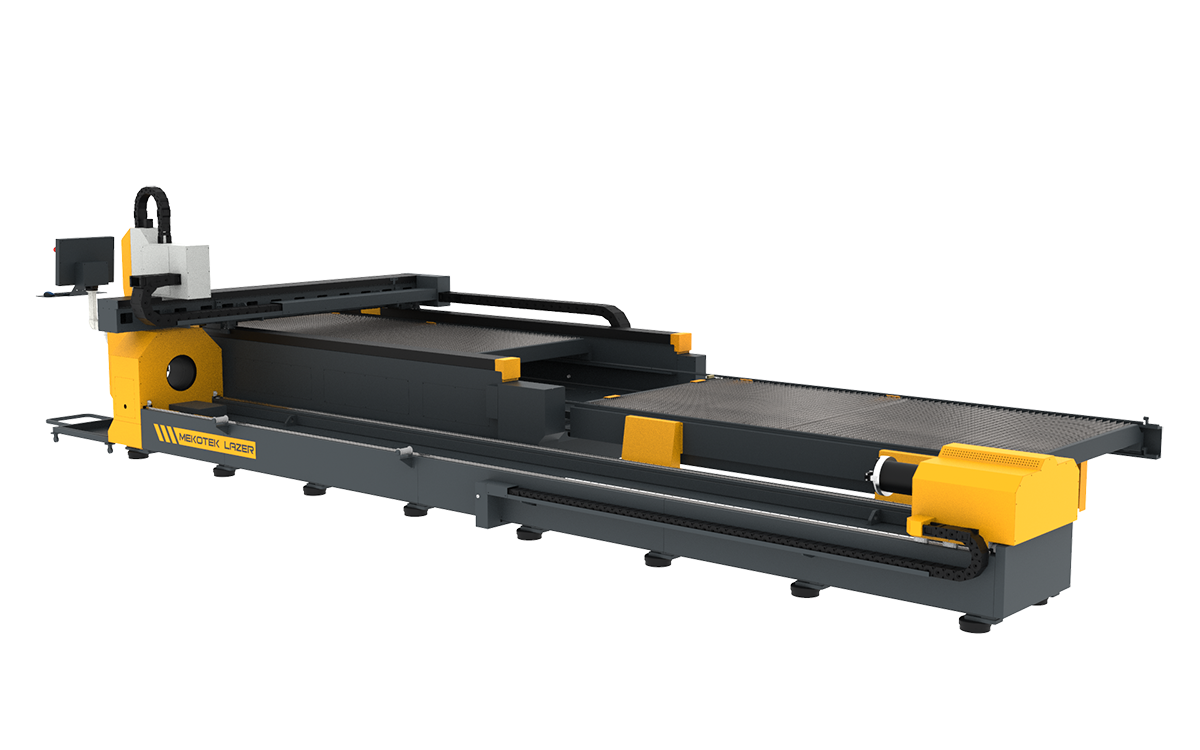

FLO-P-D 1530 - Open Type, Double Table & Pipe Profile Fiber Laser

It's a two-use machine. The FLO-P-D series cuts both metal sheets and metal profile / tube profiles with double table. You can use two separate machines with one machine, one compressor, one air system. Whether you cut a pipe profile or cut sheet metal. 1, 2 and 3kW resonators can be used in the flo-p-d model. Both sides have excellent cut quality in cuts.

Since it is a double exchance table, you can continue cutting without waiting.

All of our machines are produced in European standards and we have a CE certificate

A very good solution for fast and serial jobs.

You don't need to buy two separate machines. You can cut both sheet metal and pipe profiles.

It saves space for to its compact structure.

One machine with two uses. cuts both metal sheets and metal tubes / profile.

Standard 6 meters pipe / profile cutting length, can be 9 meters if desired.

Pipe diameter can be used up to maximum 350 mm.

Chucks can be clamping and auto-centered with one button.

Standard nesting software program, it makes the parts to be cut ready for cutting very quickly without the need for an operator. It also has flycut cutting feature.

There are 1.5x3 mt, 2x4 mt or 2x6 mt cutting area options.

Our laser head has auto focus and Active Anti-collision Function an auto view feature that detects obstacles and moves automatically.

Cutting heads have automatic cooling.

The bridges we use in all our machines are made of aluminium alloy sheet-plate welding construction type and one piece. The fact that it is one piece ensures that the bridges are rigid and prevents the bridge from maintaining its form and deforming in case of impact, overlap or strain that may be encountered. In addition, thanks to its 3 times lighter structure compared to steel profile bridges, we can output high speeds and accelerations at lower engine Powers.